Bapco bahrain jobs 2021 - Urgent hiring

Job Location: Bahrain,

Company: Leading Oil & Gas Company Babco

Required Nationalities: India,

Job Category: Oil and gas jobs

Walk-in Location: Tamilnadu,

Walk-in City: Chennai

Job Posted By: Lotus Gulf Airways Manpower & Tour Travels Agency

Post expire on: 10/13/2021

| Position | Qty | Salary |

|---|---|---|

| 1. Maintenance Mechanical Engr – Specialist in Diesel & Auto | 10.Nos | Negotiable |

| 2. Maintenance Mechanical Engr – Shutdown services materials management | 15. Nos | Negotiable |

| 3. Maintenance Mechanical Engr – Plant Heavy mechanical | 25. Nos | Negotiable |

| 4. Maintenance Mechanical Engr – Shutdown Planning | 15. Nos | Negotiable |

| 5. Grader Operator | 05. Nos | Negotiable |

| 6. Showel Operator | 05. Nos | Negotiable |

| 7. Over Head Operator | 05. Nos | Negotiable |

| 8. Light Driver -GCC Lic Must | 05. Nos | Negotiable |

| 9. Heavy Driver -GCC Lic Must | 05. Nos | Negotiable |

| 10. Fork Lift Operator -GCC Lic Must | 05. Nos | Negotiable |

| 11. Auto Electrician | 05. Nos | Negotiable |

| 12. Heavy Equipment Mechanic | 10.Nos | Negotiable |

| 13. Chiller Technician | 15. Nos | Negotiable |

| 14. Electrician | 15. Nos | Negotiable |

Job Descriptions :

Bapco bahrain jobs 2021 - Urgent hiring

1. Maintenance Mechanical Engr – Specialist in Diesel & Auto

(a) Job Qualification/Specific Requirements

(i) BSc in Mechanical Engineering or equivalent

(ii) Minimum 10 years’ relevant experience out of which at least 5 years in a Supervisory

position majorly in rotating equipment.

(iii)Experience in maintaining Rotating equipment in a petroleum refinery or petrochemical

processing industry.

(iv)Candidate should possess the following basic technical requirements:

? Knowledge on principles, practice and technology associated with installation,

operations, and Maintenance of mechanical rotating equipment of Primary & Secondary

Process units in refinery.

? Knowledge on international and company Engineering standards and procedures for

Rotating mechanical Equipment.

? Experience in troubleshooting of machinery problems.

? Good knowledge on condition monitoring techniques and their applications.

? Exposure to maintenance of Primary & Secondary Refinery Process units e.g., CDU,

VDU, Hydrocrackers, Hydrotreaters, Sulphur Plants, H2 plants, FCCU etc. & Utilities,

Boilers, Desal plants etc.

(v) Possess sound knowledge of HSE procedures and practices in petroleum Industry.

(vi)Experience with work permit system, safe work practices and carrying out / participating in

Job Hazard Analysis, risk assessment and Method Statement development as well as review.

2. Maintenance Mechanical Engr – Shutdown services materials management

(a) Job Qualification / Specific Requirements:

(i) BSc in Mechanical Engineering or equivalent

(ii) Minimum 10 years’ relevant experience out of which at least 5 years’ in a Supervisory

position majorly in rotating equipment.

(iii)Experience in maintaining Rotating equipment in a petroleum refinery or petrochemical

processing industry.

(iv)Candidate should possess the following basic technical requirements:

? Knowledge on principles, practice and technology associated with installation, operations

and Maintenance of mechanical rotating equipment of Primary & Secondary Process

units in refinery.

? Knowledge on international and company Engineering standards and procedures for

Rotating mechanical Equipment.

? Experience in troubleshooting of machinery problems.

? Good knowledge on condition monitoring techniques and their applications.

? Exposure to maintenance of Primary & Secondary Refinery Process units e.g. CDU, VDU,

Hydrocrackers, Hydrotreaters, Sulphur Plants, H2 plants, FCCU etc. & Utilities, Boilers,

Desal plants etc.

(v) Possess sound knowledge of HSE procedures and practices in petroleum Industry.

(vi)Experience with work permit system, safe work practices and carrying out / participating in

Job Hazard Analysis, risk assessment and Method Statement development as well as review

(vii) Possess basic understanding of Computer Systems and knowledge of Software such as

Microsoft Office.

(viii) Possess adequate knowledge on CMMS (Computerized Maintenance Management Systems)

and should have experience on the same.

Special Requirement Shutdown planning experience, HSE Compliance with

minimum 10 years’ experience in HSE compliance in a refinery environment

(b) Responsibilities:

(i) Create and maintain cooperative working relationships with employees, supervisors,

suppliers, vendors and contractors.

(ii)Work in a multinational environment and independently able to handle a team of

maintenance technicians and Supervisors.

3. Maintenance Mechanical Engr – Plant Heavy mechanical

(a) Job Qualification / Specific Requirements:

(i) BSc in Mechanical Engineering or equivalent

(ii) Minimum 10 years’ relevant experience out of which at least 5 years’ in a Supervisory

position majorly in rotating equipment.

(iii)Experience in maintaining Rotating equipment in a petroleum refinery or petrochemical

processing industry.

(iv)Candidate should possess the following basic technical requirements:

? Knowledge on principles, practice and technology associated with installation, operations

and Maintenance of mechanical rotating equipment of Primary & Secondary Process

units in refinery.

? Knowledge on international and company Engineering standards and procedures for

Rotating mechanical Equipment.

? Experience in troubleshooting of machinery problems.

? Good knowledge on condition monitoring techniques and their applications.

? Exposure to maintenance of Primary & Secondary Refinery Process units e.g. CDU, VDU,

Hydrocrackers, Hydrotreaters, Sulphur Plants, H2 plants, FCCU etc. & Utilities, Boilers,

Desal plants etc.

(v) Possess sound knowledge of HSE procedures and practices in petroleum Industry.

(vi)Experience with work permit system, safe work practices and carrying out / participating in

Job Hazard Analysis, risk assessment and Method Statement development as well as review.

(vii) Possess basic understanding of Computer Systems and knowledge of Software such as

Microsoft Office.

(viii) Possess adequate knowledge on CMMS (Computerized Maintenance Management Systems)

and should have experience on the same.

Special Requirement – Minimum 10 years’ experience working with oil refinery

shutdown environment and in the management of materials throughout process to

meet demands of shutdown

(b) Responsibilities:

(i) Create and maintain cooperative working relationships with employees, supervisors,

suppliers, vendors and contractors.

(ii)Work in a multinational environment and independently able to handle a team of

maintenance technicians and Supervisors.

4. Maintenance Mechanical Engr – Shutdown Planning

Job Purpose

As the Companies Technical Specialist this function provided internal expertise to the

company. To oversee, direct, co-ordinate and optimize the most appropriate

maintenance, repair, service, or overhaul of Company’s automotive equipment, including

all stationary and mobile internal combustion engines and related equipment.

II. Dimensions

Ensure control of staff, material and equipment used by the Diesel & Auto group. As

Company Specialist has overview & direct technical influence on the extent, duration,

and cost of repairs to be conducted on auto equipment. Directly influences the economic

life of the Company fleet and its availability by selection of best maintenance practices.

Operation Budget: $420,000 Staff Reporting Direct: 2 Supervisors, 1 Planner, 1 Inspector

Capital Expenditure: $1-150,000 Other: Total Staff of 14 + Contractors

III. Key Result Areas

1. Advisory role for staff work schedules in order to ensure adequate 2 shift cover seven

days a week by field staff, & specialist availability to meet scheduled work. Monitors &

approved the TAA system for his staff to facilitate correct payment.

2. Review maintenance activities and procedures; develop vehicle/equipment preventive

maintenance schedules in accordance with the age, service and condition of the

equipment for improvement in operations and reduction in cost. Also reviews related

Q.A. procedures to ensure asset integrity & safety. Maintains progress status on all

repairs being carried out to ensure optimum turn around.

3. Prepares conditional reports, accident repairs cost estimation, work carried out also

projected work, plans and schedules. Collection and presentation of information on

vehicle and costs & statistics to ensure economic life & repair policies.

4. Prepares to respond to all emergency calls at any time to ensure the availability of

emergency equipment. On 24/7 Fire Call.

5. Personally tests, approved and passes for service any vehicle or engine unit assembly

where a special decision, modification or adoption is required.

6. Assist pre-qualifying contractors tendering for company equipment repair terms

contract and prepares contract technical specification and costing for all company light

& heavy plant equipment and stationary engines. Monitors contracted job costing and

report on regular basis indicating spent against available budget and conducts regular

visit to contractor workshop to ensure work quality & cost control.

7. Raises Purchase Orders & associated paperwork for equipment repair to his

Superintendent of fund approval on regular basis to provide auditable records.

8. Approves inspection list for all company vehicles/equipment for annual registration

renewal at the “Traffic Department” to satisfy National requirements.

9. Trade test all contractor’s mechanics and Auto electricians work on company premises

& approves contractor mechanics and Auto electricians to work on company.

10.Approves “Crane Certificate of Worthiness” to ensure site cranes are safe, efficient and

available. Also ensures that the Safety Enhanced Devices fitted are tested.

IV. Job Context

Provides a broad-based Garage & Auto/diesel service to Company including inspection of

all contractor engine driven equipment that enters site. Responsible for the upkeep and

inspection of approximately 227 vehicles/items of equipment valued at approximately

$10,000,000.

V. Communications and Working Relationships

Direct and controls a section of 14 Company’s Supervisors, technicians and craftsmen of

various skills and competency as well as overseeing the monitoring and control of the

Service Contractors activity by visiting & discussion with the Supervision and auditing

the activities at the Contractors Workshops. Has regular interaction with materials

Department staff at all levels. Regularly communicates with his Superintendent to

discuss issues, provide, or receive information & guidance. Supports his supervisors in

organizing with Contractors, Security Department and Shutdown & Major Maintenance

for inspection and certifying all contractor’s auto equipment which will be used in the

Company’s premises.

VI. Framework Boundaries, Decision Making authority and responsibility

While operating with the minimum of supervision in matters of craft skills and

knowledge, there is guidance on matters relating to job priorities. There is limited scope

for independent action without referral to higher or external authority, with most work

covered by standards, procedures, or custom-and-practice.

No financial authorities for purchasing but with regularly initiate parts, materials, or tool

requirements. Can initiate and draw spare parts and materials from the site stores

system. Mistakes or failure to exercise appropriate control could lead to serious injury or

costly damage.

Directly responsible for the quality of service and repair of all vehicles and Auto

equipment carried out by Company workforce or by Contractors. Monitors the work

carried out by Contractors in order to control the cost and quality of workmanship with

particular attention to cranes, Fire Engines & Ambulances due to the critical nature of

the service they perform.

There is a considerable measure of latitude for independent decision making as

Specialist up to his limit of authorization. Assists in the preparation of technical

specifications for contracts for all Diesel & Auto equipment’s as well as conducting pre-

qualification of Contractors.

VII. Knowledge Skills and Experience

1. BSc in Mechanical/Automotive Engineer

2. Ten years’ experience relevant experience of which four must have been at

Supervisory level.

3. Good organization and leadership skills.

4. Comprehensive knowledge of the Company’s operational requirements.

5. Good communication skills-English written & verbal. Able to write detailed technical

reports and recommendations.

6. Appreciation of Safety issues related to Cranes SLI (Safe Load Indicators) and

Safety Enhanced Devices. (i.e PYROBAN System)

7. Appreciation of Empac System and in particular the planning function. (at times

relieve planner).

Desired candidate profile :

All the above categories must experience in Oil & Gas Gulf Rtn Only All the candidates send to CV and other support documents office mail id : Email id: lotusdelhicv@gmail.com

· Update Resume only in Word Format with contact & other necessary Details.

· Passport copy & trade test certificate for technical categories PDF File Only .

· Flight will be from Chennai only

· Accommodation, food, Transportation, & COVID 19Medical Vacines Certificates must

Benefits provided by company :

Period of Contract - 2.yrs

Accommodation - Provided by the company

Food Allowances - Not provided by the company

Overtime - As per Bahrain labour law

Mode of Interview - Zoom or Skype

Click on the above 'Apply Button' & send your details to the recruiter, then recruiter will contact you after checking your details.

Disclaimer:- GCCWALKINS have no involvement in any recruitment process, This website just sharing job vacancies & interviews from various sources. Applicants are advised to research the bonafides of the prospective employer independently. We do NOT endorse any requests for money payments and strictly advice against sharing personal or bank related information. If you suspect any fraud or malpractice, email us at gccwalkins@gmail.com

Gulf Jobs By Cities

- Gulf job interviews in Mumbai

- Gulf job interviews in Chennai

- Gulf job interviews in Cochin

- Gulf job interviews in delhi

- Gulf jobs interview in hyderabad

- Gulf jobs interview in Kolkata

- Gulf job walkins in Bangalore

- Gulf jobs interview in trichy

- Gulf jobs interview in trivandrum

- Gulf jobs interview in calicut

- Gulf jobs interview in patna

- Gulf jobs interview in vadodara

- Gulf jobs interview in madurai

- Dubai jobs interview in Mumbai

- Dubai jobs interview in Chennai

- Dubai jobs interview in Bangalore

- Dubai jobs interview in Delhi

- Dubai jobs interview in Kolkata

- Dubai jobs interview in Hyderabad

- Dubai jobs interview in Kerala

Gulf Jobs By Recruiters

- Jerry Varghese Gulf Jobs

- Assignment Abroad Times Gulf Jobs

- RK International Gulf Jobs

- Ambe International Gulf Jobs

- Gheewala Gulf Jobs

- Seagull international Gulf Jobs

- Asia power Gulf Jobs

- Indman Consultants Gulf Jobs

- Travel Point Gulf Jobs

- Premier Travels Gulf Jobs

- Dynamic Staffing Services Gulf Jobs

Gulf jobs by Country

- Jobs in dubai for Indian

- Jobs in qatar for Indian

- Jobs in UAE for Indian

- Jobs in saudi arabia for Indian

- Jobs in kuwait for Indian

- Jobs in oman for Indian

- Jobs in bahrain for Indian

- Jobs in russia for Indian

- Jobs in canada for Indian

- Jobs in mauritius for Indian

- Jobs in USA for Indian

- Jobs in Singapore for Indian

- Jobs in UK for Indian

- Jobs in Australia for Indian

- Jobs in sweden for Indian

- Jobs in new zealand for Indian

- Jobs in europe for Indian

- Jobs in bangkok for Indian

- Jobs in switzerland for Indian

- Jobs in africa for Indian

- Jobs in italy for Indian

- Jobs in france for Indian

- Jobs in poland for Indian

- Jobs in hong kong for Indian

- Jobs in thailand for Indian

- Jobs in denmark for Indian

- Jobs in jordan for Indian

- Jobs in malta for Indian

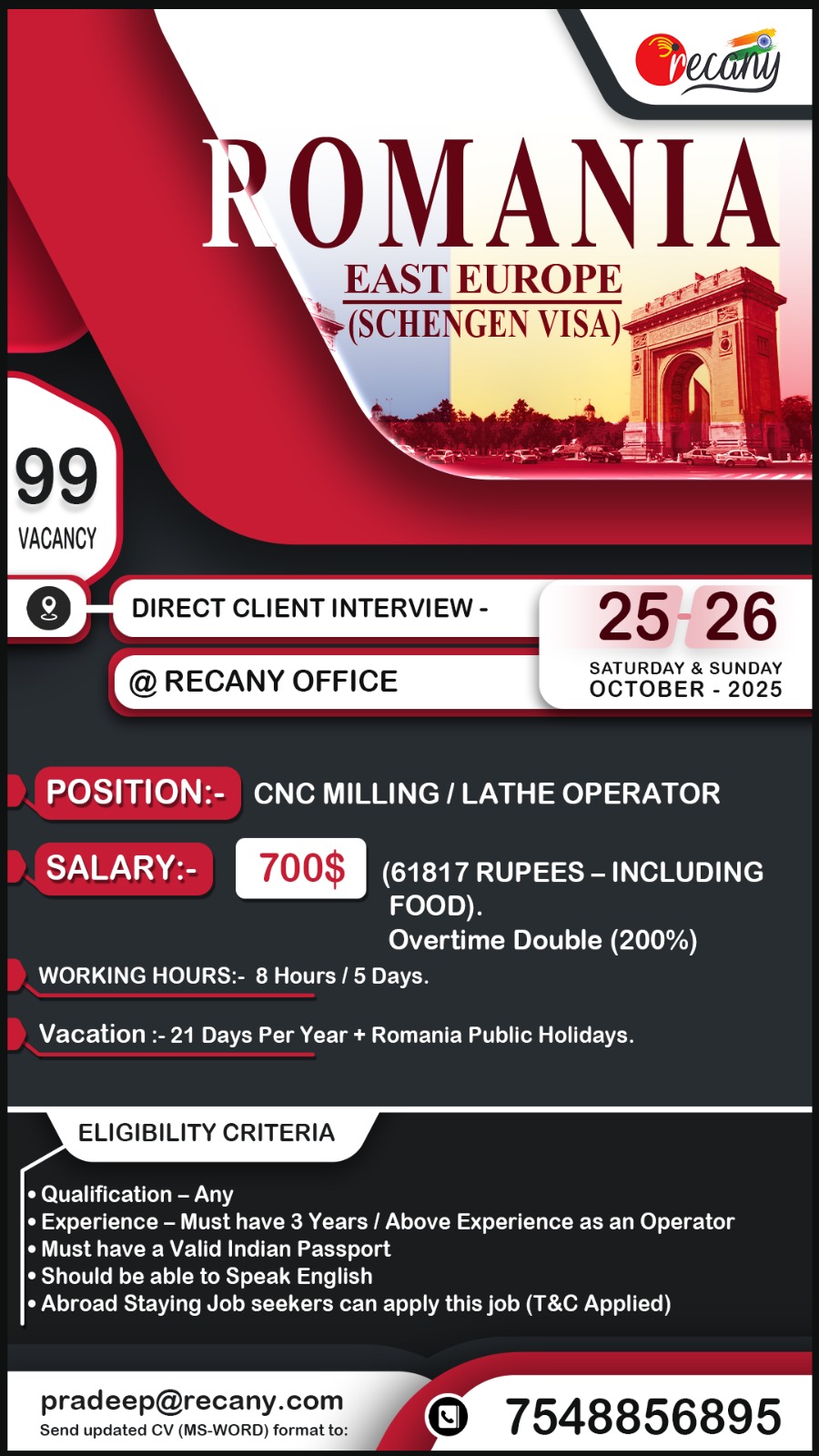

- Jobs in romania for Indian

- Jobs in serbia for Indian

Gulf jobs by designation

- Safety officer jobs in gulf

- Teaching jobs in gulf

- Piping engineer jobs in gulf

- Mechanical engineering jobs in gulf

- Store keeper jobs in gulf

- Document controller jobs in gulf

- Civil engineering jobs in gulf

- Instrument technician jobs in gulf

- CCTV technician jobs in gulf

- Welder jobs in gulf

- Civil foreman jobs in gulf

- Land surveyor jobs in gulf

- Autocad draftsman jobs in gulf

- Welding inspector jobs in gulf

- Plc scada jobs in gulf

- Safety engineer jobs in gulf

- Hvac engineer jobs in gulf

- Medical coding jobs in gulf

- Fire and safety jobs in gulf

- Piping designer jobs in gulf

- Accountant jobs in gulf

- Electrical technician jobs in gulf

- Nurses job vacancy in gulf

- Electrician job in gulf

- Autocad job in gulf

- Mobile crane operator jobs gulf

- Electrical engineering jobs in gulf

- Electrical supervisor jobs in gulf

Recently Added Gulf Jobs

- Garments jobs in russia for Indian - Garments/Uniform

- Russia warehouse jobs for Indian - Nestle Warehouse Russia

- Urgent jobs in Russia for Indian - Multiple Companies

- Hafilat transport company dubai vacancy - Walk in Interview

- Alemco company dubai vacancy - Walk in Interview

- Berkeley company Dubai vacancies - German Based Company

- Urgent House keeper jobs in UAE Star Hotel

- Medgulf qatar vacancies 2025 - Walk in Interview

- Adeeb Group Dubai Job Vacancies - Walk in Interview

- Urgent job vacancies in Dubai - Project Management Company

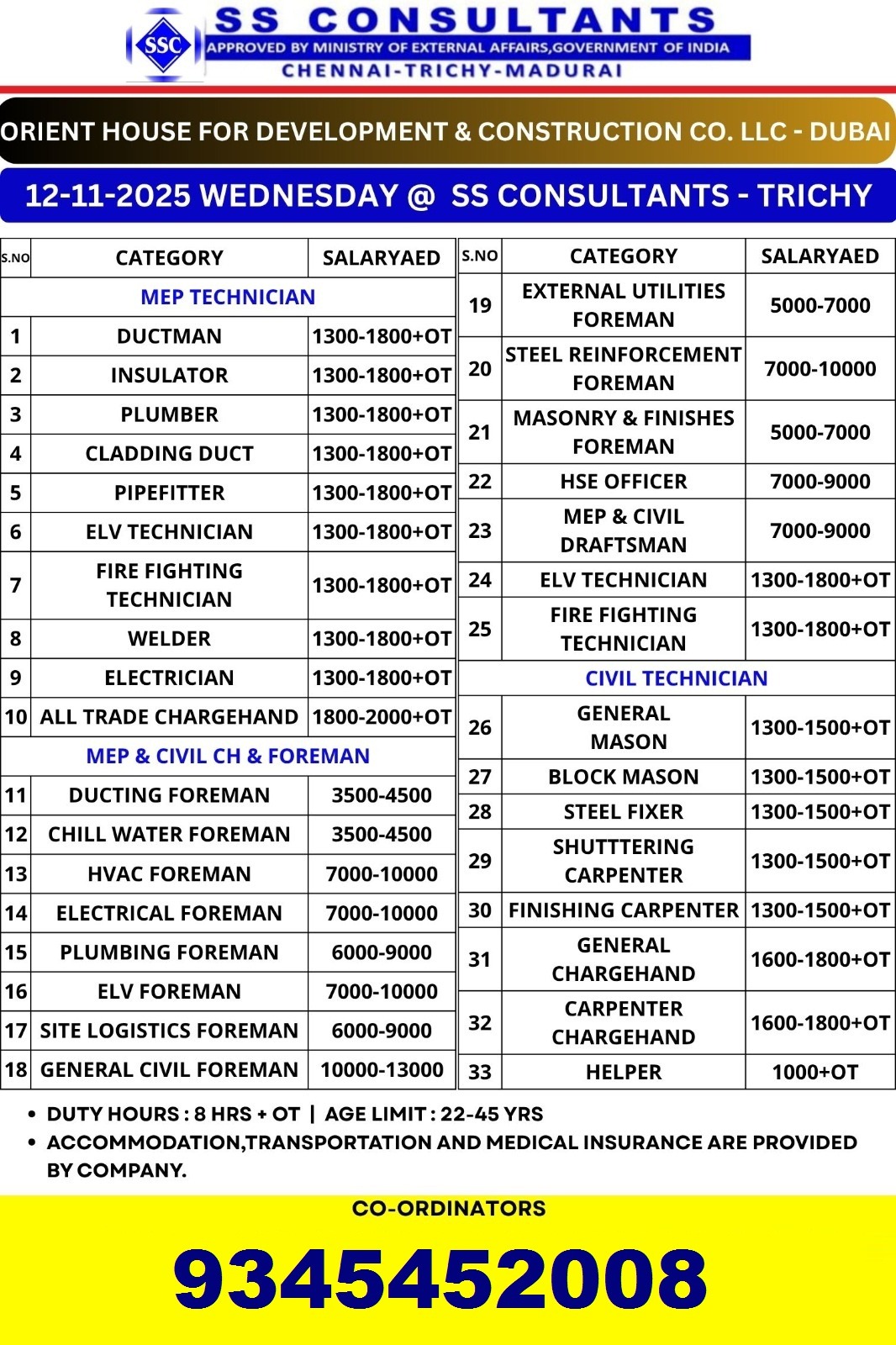

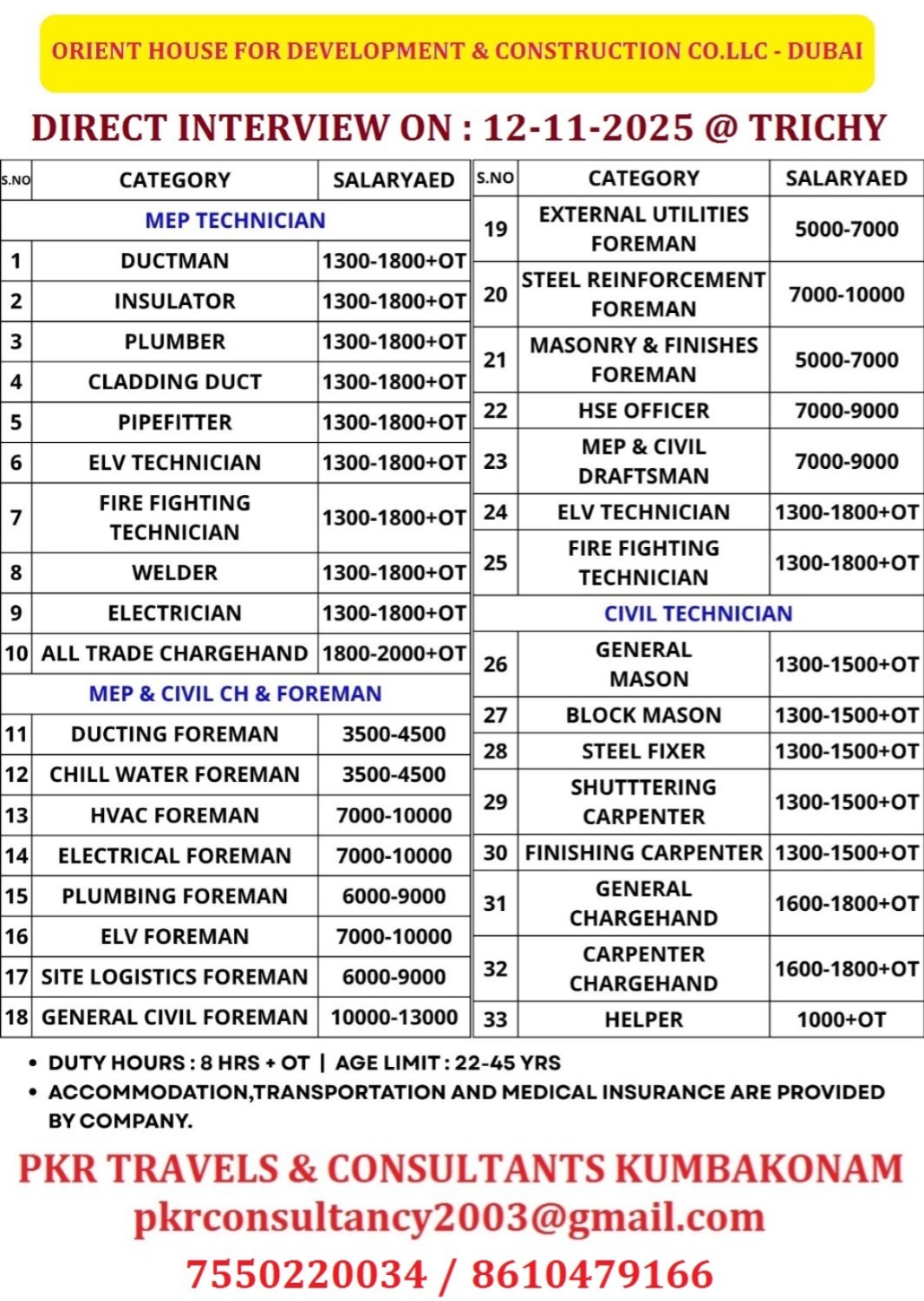

- Orient House Company Dubai jobs - Large recruitment

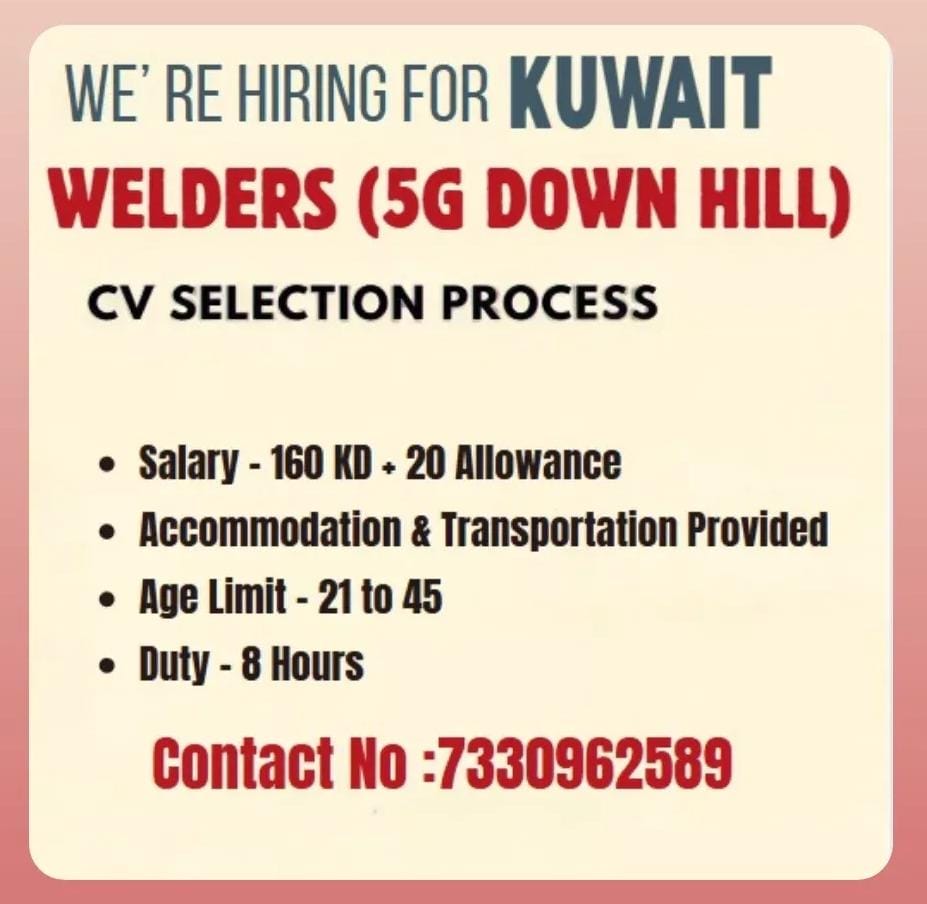

- 5G Welder job vacancy in Kuwait - Urgent hiring

- Urgent requirement for Kuwait

- Equate kuwait shutdown 2025 vacancy - Free recruitment

- Orient House for Development Construction jobs Dubai - Large recruitment

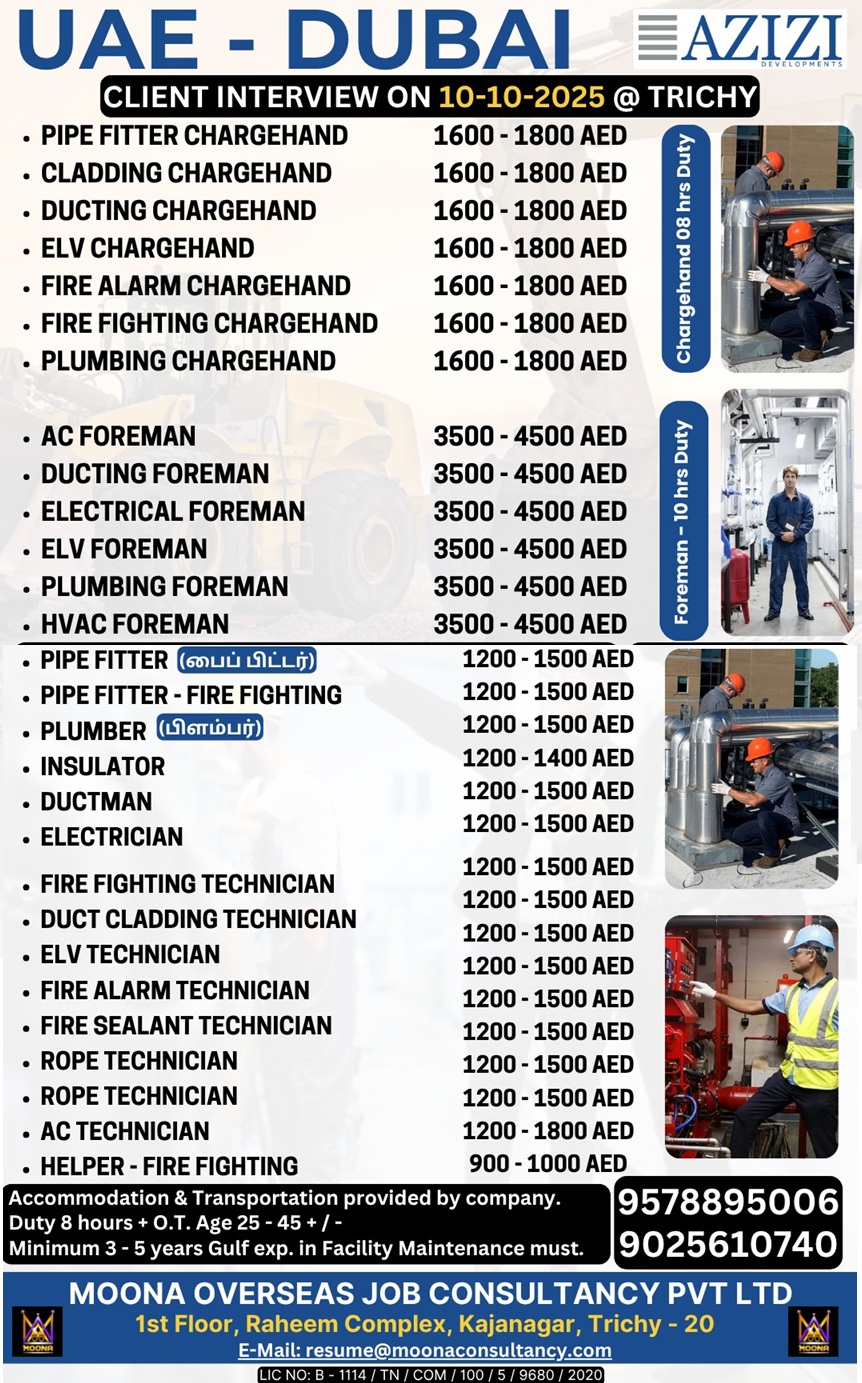

- Azizi company Dubai vacancy - Large recruitment

- Furniture Carpenter jobs in Dubai - DUCTO Interiors

- Dussmann gulf llc dubai jobs vacancies - Walk in Interview

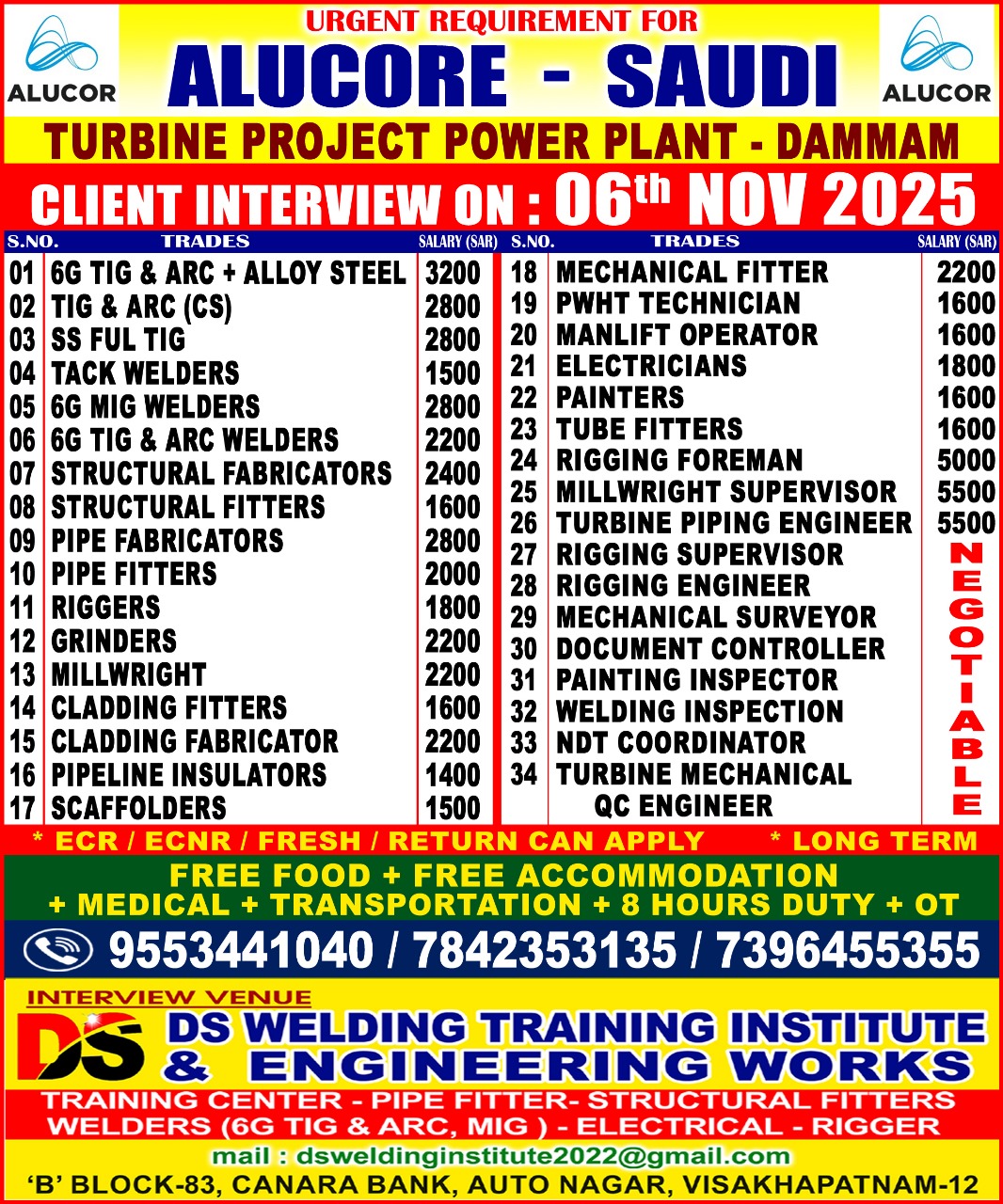

- Alucor saudi arabia job vacancies - Walk in Interview

- Juma Al Majid Group Vacancy Dubai - Walk in Interview

- Urgent delivery driver job in kuwait - Fresh indian light drivers

- Urgent job vacancies in Abu Dhabi - Fire fighting & Fire Alarm Project

- Danube group dubai jobs vacancy - Free recruitment

- Albaik saudi arabia jobs interview - Free recruitment

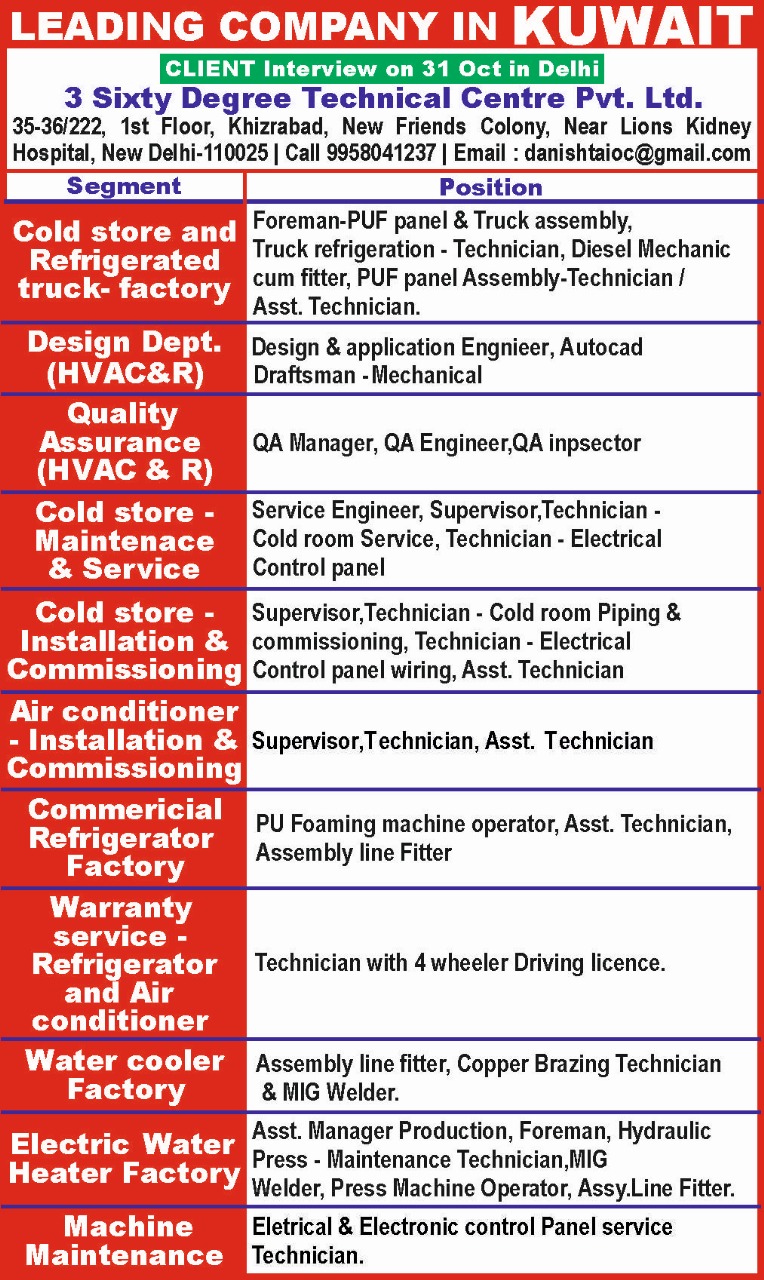

- Recruitment to Kuwait - Walk in Interview

- Tk elevator saudi arabia jobs - Free recruitment

- Hiring for OTIS Elevators Hyderabad

- Recruitment to Kuwait - Client Interview

- Al Faris Group job vacancy - Recruitment to UAE

- Petrojet Abu Dhabi vacancies - Oil and Gas Project